Home

Thoughtfully designing products and systems for tomorrow

Healthier materials for a healthier planet

Globally, we currently generate some 2.5 billion metric tons of waste per year for a population that’s expected to increase by roughly 33%, to 9.2 billion people, by 2050 (as projected by the United Nations). Much of this waste is plastic, which persists in our landfills, as well as in our oceans, and endangers human, animal and ecological health. At the New Materials Institute, we think it’s time for a paradigm shift in waste management; that a material’s useful end-of-life should be considered at the design stage and that Green Engineering principles should be part of this process.

The NMI welcomes partnerships. We work with a wide range of partners to pioneer systems and materials that promote circularity, for proactive materials management. Whether it be circular materials management systems at the municipal to global scale, or innovative and biologically degradable materials and products that meet the high expectations of industry and the consumers they serve, we take a holistic approach to your issues. As we work, we’re also training the next generation of engineers and scientists, so that they consider our context-driven and Green Engineering design approach in all they do.

Home of the Bioseniatic℠ Laboratory

Our Bioseniatic℠ Laboratory offers testing for any material or product currently in development or use that meets our criteria—from any researcher or manufacturer. Bioseniatic™ materials and products represent a new generation of biologically-degradable materials and/or products that are consumed by microbes in the receiving environment—even your backyard. Bioseniatic™ materials and products may come from nature or be synthetic, but regardless of their source, all are microbially degraded and non-toxic, which makes them safe for animals, people and our planet.

By working with our industry partners who seek to shore-up consumer confidence in their products, we are striving to correct confusion which has been brought about by the marketing terms “biodegradable” and “compostable.”

Join our waste-prevention revolution

Work with us, as we take your product, product idea, or system to our bench and thoughtfully design it for tomorrow.

UGA New Materials Institute seeks funding for sustainability project

Research from the UGA New Materials Institute found that of all plastics manufactured globally from the onset of their mass production, which followed World War II, only about 9% had been recycled. Ironically, this includes plastic trash cans, or “wheeled bins”, which—granted—are manufactured ongoingly, globally, in varying sizes, for long-term use and a variety of tasks, from residential curbside pickup by solid waste management companies, to composting, to recycling, storage of animal feed, etc. According to MarketResearchFuture.com, the global market for wheeled bins manufactured from plastic, metal, or composite materials, in 2023 was valued at $6.34 billion. Meanwhile, in the U.S.A., there is a growing household demand for wheeled bins.

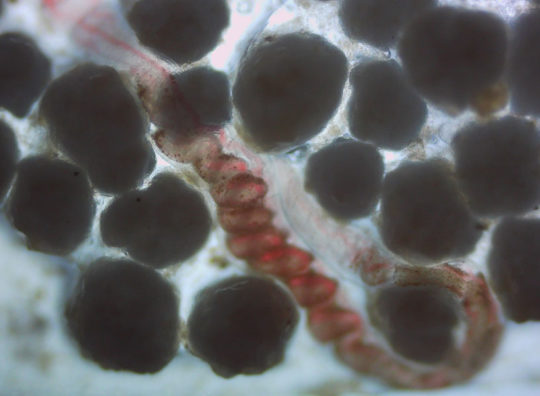

PHA-based microbeads, made from UGA-developed technology, biologically degrade in wastewater treatment facilities

A diverse ecosystem of microinvertebrates and -fauna was witnessed by researchers at the UGA New Materials Institute during field and laboratory studies to evaluate the degradation of cosmetic microbeads made from a polyhydroxyalkanoate, or PHA, polymer developed at the Institute. In the upper-right corner of this video, you can see a reddish-colored worm, or nematode. Smaller organisms are seen moving elsewhere within the microbeads and wastewater. As these organisms consume the carbon-based material, their digestive and metabolic processes degrade the microbeads ultimately into CO2. Microbeads in this study degraded in 15 weeks in laboratory conditions, and 13 weeks in field conditions.