Research Facilities and Equipment

The instrumentation toolset available at the University of Georgia New Materials Institute specializes in polymer and composite analysis with a focus on understanding the performance of new materials during processing, service life and end-of-life. Our team’s unique approach to partnerships with industry and our motivation to solve the world’s most pressing problems with incumbent plastics are central to the processing equipment and characterization instrumentation roster in our facilities.

Additionally, the UGA Office of Research provides an array of complementary Core Facilities & Research Services that are available to researchers at UGA, other universities, government agencies, nonprofit organizations and industry.

The UGA New Materials Institute primarily operates out of the Riverbend Research Laboratory complex, where approximately 3,500 square feet of laboratory space is dedicated to research and development efforts on new and existing materials used in single-use and coatings applications.

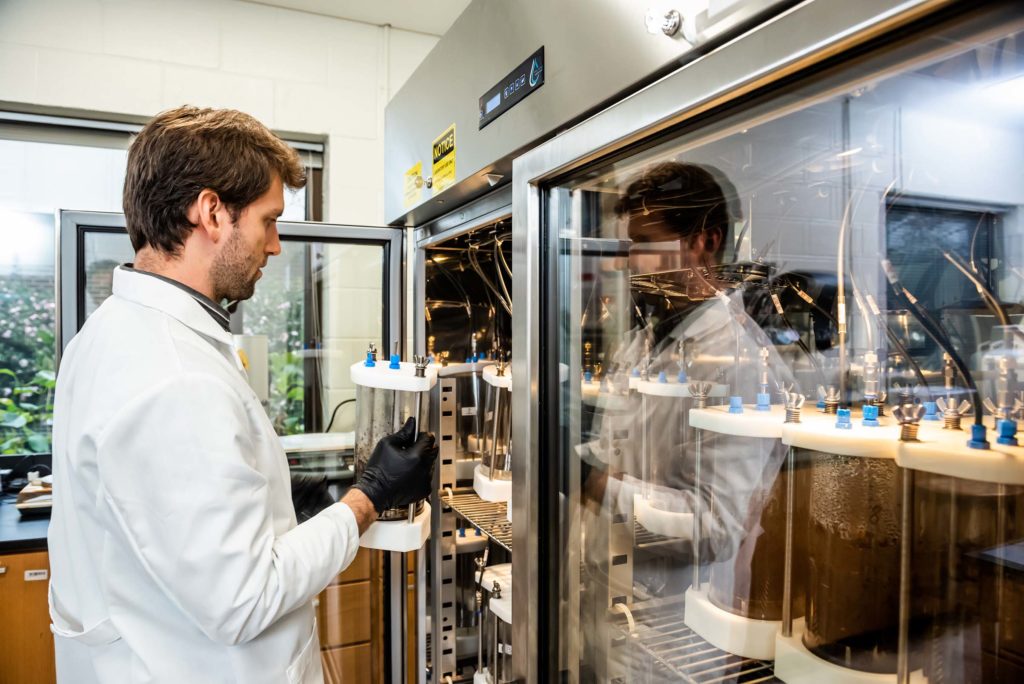

The equipment below is available at the New Materials Institute. Some of this equipment is used by our Bioseniatic℠ Laboratory, as part of our analytical and certification process for Bioseniatic™ materials and products. The UGA New Materials Institute has constructed some of the largest respirometers in North America for its biological degradation studies, totaling 252 chambers for environmental simulation.

Processing and Synthesis Equipment

- HAAKE MiniLab II micro compounder, conical twin-screw, approximately 8-10 gram minimum.

- HAAKE MiniJet II Injection Molding System; 12,000 bar max; 250°C maximum mold temperature; 400°C maximum cylinder temperature.

- Carver compression press, both platins heated.

- Heidolph rotary evaporators, 100-760 torr, 20-100°C.

- BÜCHI R-124 rotary evaporator for synthesis, 0.10-760 torr, 20-300°C.

- Mettler Microbalances, 0.01 mg resolution.

- Labconco high-vacuum drying and lyophilization.

- Cryogenic Mill.

- FDM, SLA, and SLS 3D Printers.

- Automatic Drawdown Coater.

- Hot Melt Coater Laminator HLCL-2000.

- Glen Mills Inc TURBULA Shaker/Mixer.

Analytical Equipment

- KRÜSS DSA100 Drop Shape Analyzer.

- Thermo Scientific Varioskan LUX.

- Labthink PERME® W3/230 Water Vapor Transmission Rate Test System.

- TA Instruments DSC250, Differential Scanning Calorimeter, -90°C-550°C.

- TA Instruments Discovery Series TGA-MS; 0.1-500°C/minimum in linear control or up to 2000°C/minimum in ballistic heating over the range ambient to 1,200°C maximum temperature; online quadrupole mass spectrometer (0-300 m/z).

- TA Instruments DHR-2, Discovery Hybrid Rheometer; 600°C maximum; 200 mN.m maximum torque; 300 rad/s maximum angular velocity.

- Brookfield-Ametek RVDV3T Extra Rheometer (rotational viscometer).

- TA Instruments Q800 Dynamic Mechanical Analyzer; 18 N maximum force; 0.00001 N force resolution; -100°C-600°C; 5-95% RH control.

- TQC Sheen Pendulum Hardness Tester, for ASTM D4366, ISO 1522 (2005), NBN T22-105, BS3900 E5.

- Shimadzu AGS-X 1kN tensile tester.

- Labthink C680M Tearing tester, for ISO 6383-1-1983, ISO 6383-2-1983, ISO 1974, GB/T 16578.2- 2009, GB/T 455, ASTM D1922, ASTM D1424, ASTM D689, TAPPI T414.

- Malvern OMNISEC Resolve and Reveal GPC/SEC (triple detection).

- Shimadzu LC-20AD, equipped with RID-10A Refractive Index Detector and UV254 nm detector.

- Agilent 1100 Series HPLC.

- Agilent Gas Chromatography, 6890 Series GC System.

- Varian Cary® 50 Bio UV/Vis spectrophotometer.

- ThermoFisher Nicolet 6700 FTIR, equipped with GATR accessory.

- Bruker Nanoscope V Multimode AFM, equipped with peak-force quantitative nanomechanical mapping (PF-QNM).

- Bruker Anasys NanoIR3 Atomic Force Microscopy-Based Infrared Spectroscopy (AFM-IR).

- Thermo Nicolet Avatar 380 FTIR.

- Linkam Polarized Optical Microscope.

- Malvern Panalytical Morphologi 4-ID, Morphologically-Directed Raman Spectroscopy (0.5 μm -1300 μm particle range).

- Malvern Panalytical Zetasizer Nano ZS Analyzer, 2-angle particle and molecular size analyzer.

- Malvern Mastersizer 3000 Particle Size Analyzer Distek Dissolution System 2500.

- (1) ECHO 12-channel respirometer; equipped with online O2 (0-20%), CO2 (0-5000 ppm), and CH4 (0-5%) detectors. Dedicated mass flow controllers and flow analyzers (0-500 mL/min per channel) for continuous sampling.

- (3) ECHO 60-channel respirometer; equipped with 36 online O2 (0-20%), CO2 (0-5000 ppm), and CH4 (0-5%) channels, and 24 online O2 (0-20%), CO2 (0-30,000 ppm), and CH4 (0-10%) channels. Dedicated mass flow controllers and flow analyzers (0-500 mL/min per channel) for continuous sampling.