Pharmaceutical Development Utilizing HME

Hot Melt Extrusion (HME) for Pharmaceutical Development

The University of Georgia New Materials Institute offers a wide variety of expertise for the pharmaceutical industry’s development of solid oral dosage forms utilizing hot melt extrusion (HME). Development of suitable excipients through solubility match using Hansen Solubility Parameters in Practice (HSPiP) software allows for streamlining of the formulation process. Bench scale to semi-pilot scale extrusion allows for conservation of valuable materials during early phase development while allowing for the option to upscale to conventional twin screw extruders.

Better Medicine

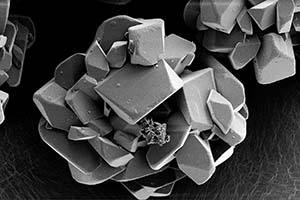

Amorphous Solid Dispersions (ASD) allow for better bioavailability of poorly soluble and highly crystalline materials. HME allows for high shear and high temp mixing to maximize distribution of the active pharmaceutical ingredients (API) in the chosen solid form while maintaining a relatively short residence time. Advanced analytical techniques such as dynamic scanning calorimetry (DSC), polarized optical microscopy, X-ray diffraction, Liquid Chromatography-Mass Spectrometry (LC-MS) allow for full characterization of developed ASDs. Release profile of the API can be monitored through dissolution in a variety of media.

The New Materials Institute also has experience in developing delayed release dosage forms with a variety of excipients and APIs with the possibility of more complex structures being generated through compounding and injection molding.

Equipment

- Haake Minilab II Conical Twin Screw Extruder

- Haake Minijet Injection Molder

- Process 11 Twin Screw Extruder

- Leistritz 18mm Twin Screw Extruder

- Polarized Optical Microscopy with Linkam THMS600 Thermal Stage (-196°C to 600°C)

- Dynamic Scanning Calorimetry

- Parallel Plate Rheometry

- Dynamic Mechanical Analysis (DMA)

- Tensile Tester

- Scanning Electron Microscope (SEM)

- X-Ray Diffraction Analysis (XRD)

- Tablet Press

- Liquid Chromatography-Mass Spectrometry (LC-MS)

- High-performance Liquid Chromatography-Mass Spectrometry (HPLC-MS)

- Gas Chromatography-Solid Phase Microextraction (GC-SPME)

- Texture Analyzer

- Helium Pycnometor

- Atomic Force Microscopy-Infrared Spectroscopy (AFM-IR)

- Fourier Transform Infrared Spectroscopy (FTIR)

- Dissolution Bath

- Thermogravimetric Analysis coupled with Mass Spectrometry

- Nuclear Magnetic Resonance Spectroscopy (NMR)

- Friabilator tester

- Tablet Hardness Tester

- Disintegration Tester

- Automated Tap Tester

- Flodex

- Gel Permeation Chromatography (GPC)

- Morphologi 4 Raman Microscope

- Mastersizer 3000 Particle size Analyzer

- Izod Impact tester

- Fused Deposition Modeling (FDM) and Selective Laser Sintering (SLS) 3D printers