The Athens-Clarke County Solid Waste Department and the University of Georgia New Materials Institute are looking for up to 400 households in Athens to test their new Residential Compost Pilot Project, which will be deployed in February and end in early May.

Residents in the Normaltown and Boulevard communities are eligible to register for participation in the study, which tests a residential curbside food scrap collection program. In addition, multiple food scrap drop-off locations will service the collection zone for all residents. ACC will not assess additional collection fees to the homes that participate in the pilot project.

“More than one-fifth of all landfilled garbage is food waste, much of which is generated in our homes.”

Evan White, a co-investigator on the project team.

“More than one-fifth of all landfilled garbage is food waste, much of which is generated in our homes,” said Evan White, a co-investigator on the project team. “Only one-fifth of landfills in the U.S. currently collect methane for energy production. So, diverting food scraps to facilities that recycle these scraps into compost, along with other organic materials, is an easy way for families to reduce their carbon footprint. ACC is selecting single-family homes, which represent more than half of the U.S. population.” White serves as director of the UGA New Material Institute’s Bioseniatic SM Laboratory, which studies how materials degrade in various environments, like landfills, industrial composting sites and municipal wastewater treatment plants.

Methane is the primary gas produced from landfilled food waste. While it lives in Earth’s atmosphere for a shorter time than carbon dioxide, the U.S. Environmental Protection Agency estimates that methane is 28 times more effective than carbon dioxideat trapping heat in the atmosphere. The International Energy Agency says methane is responsible for about 30% of the rise in global temperatures since the start of the industrial revolution.

“The ACC Solid Waste Department is excited to participate in this pilot project,” said Suki Janssen, department director. “Our hope is to craft a residential program for the Athens community with the lessons learned from this project.”

The company will temporarily provide participating homes with a metal wheely bin designed to be lifted—or “tipped”—by existing collection truck lifts, facilitating easy collection for haulers and familiar routine curbside pickup for homeowners. The company will service all home collection bins weekly during the study period.

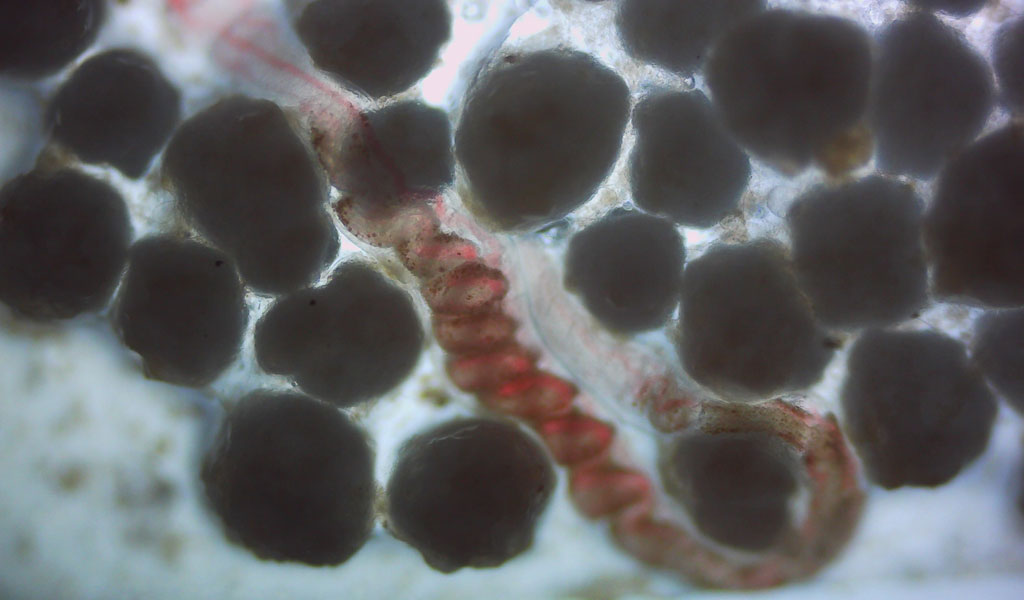

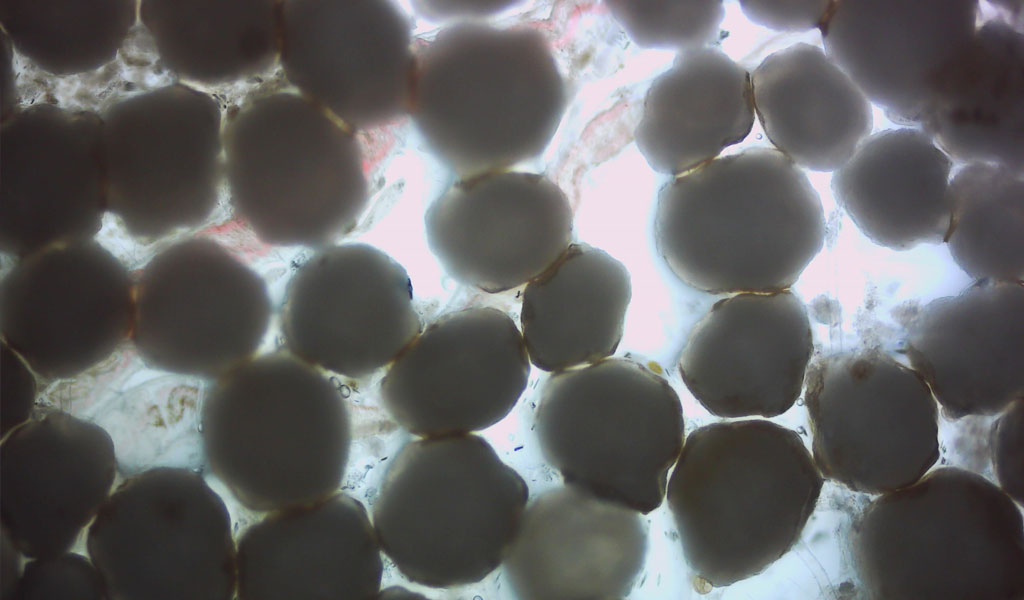

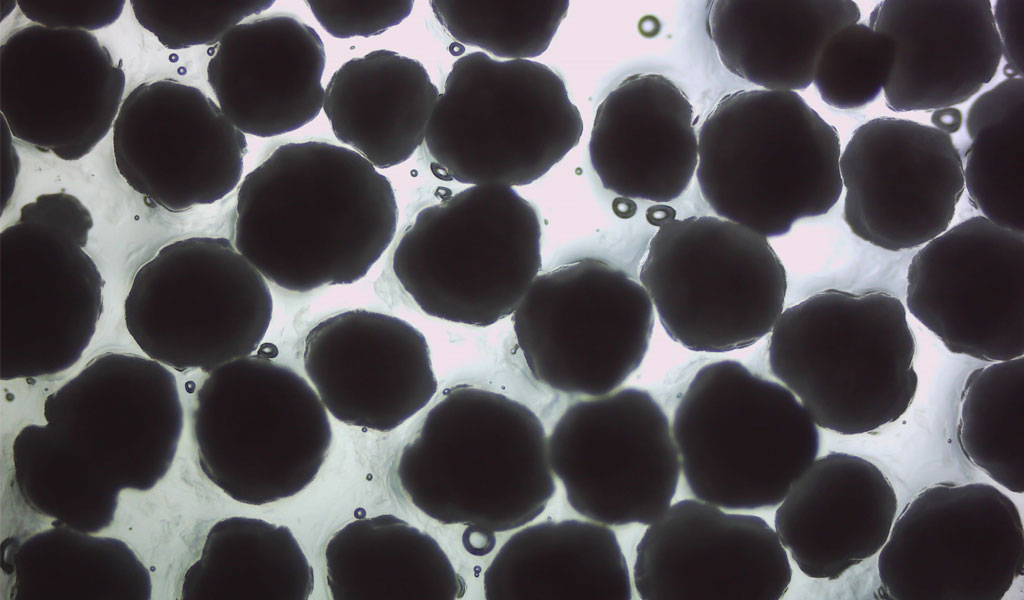

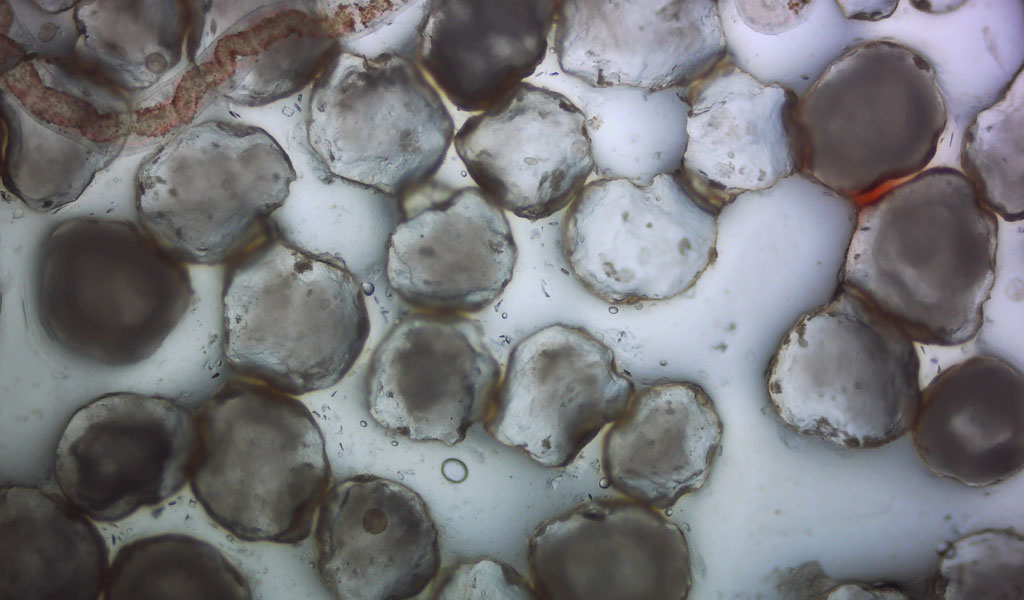

In keeping with the pilot program’s focus on recycling, the company designed all the bins to have a recycling or composting end-of-life and to reduce odors and access by pests. The company selected metal as a material for the residential pickup bins to avoid generating microplastics during in-service use, which occurs with environmentally persistent plastic garbage bins as they degrade. The company purchased the metal cans from U.S. steel manufacturers Behrns Manufacturing (www.behrens.com), located in Excelsior, Minnesota, and had them fabricated to adapt to ACC’s automated lift trucks by Dye Sheet Metal (http://www.dye-sheet-metal.com) of Bogart, Georgia.

In addition to the curbside collection program, the company will place several larger solar-powered autonomous composting bins at drop-off sites in the two communities, making them accessible to all residents. The company will position these solar-powered units, designed by faculty at the New Materials Institute, where curbside pickup is not possible. At the end of their service life, most of their mass (excluding electronics) can be composted, depositing their carbon into the composted soil.

“Our findings will help Athens and other cities understand the viability of such a program, the demand for organics recycling, and how to navigate the collection logistics,” said White.

The pilot program is part of a two-year study, funded by the Walmart Foundation, aimed at improving circular systems related to the collection, recovery and management of organics waste. ACC Solid Waste will manage this portion of the study, while the New Materials Institute team will analyze the collection data.

Other UGA members of the study team include Jason Locklin, director of the New Materials Institute, and head of the Department of Chemistry; Jenna Jambeck, the Georgia Athletic Association Distinguished Professor in Environmental Engineering and lead of the Circularity Informatics Lab; and Branson W. Ritchie, Distinguished Research Professor, director of technology development and implementation for the Institute, and co-director of the Infectious Diseases Laboratory.

To sign up for the program, visit www.accgov.com/composttrial. Registration for curbside service will end when 400 residences within the service area have committed to participate.

—

Writer/contact: kygilmor@uga.edu or emwhite@uga.edu.